Treatment Record:

SPEED brackets were bonded to upper and lower 6-6. Composite was bonded to the occlusal surface of each of the

lower first molars to open the bite and prevent interference between the upper incisors and lower anterior SPEED

brackets.

Maxillary Arch

Initial alignment was achieved with .014 Light Force Heat Activated Nickel Titanium, followed by round .018 Stainless

Steel with open coil spring to open space for the upper left canine. Closed coil was then inserted to hold space for the

upper left canine, pending surgical exposure. Following surgical exposure, the canine was bonded and .014 Nickel

Titanium was used for alignment. A .018 x .025 Stainless Steel wire was used for archform coordination, followed by

.021 x .025 Stainless Steel for full expression of appliance prescription and final arch form.

Mandibular Arch

Light force heat activated wires were used for initial alignment of centrals and posterior teeth, bypassing the ectopic

lower lateral incisors. As alignment resolved, open coil springs were used to close the space distal to the first premolar

and correct lingual inclination of the lower central incisors. Arch form was initiated with .018 x .025 Stainless Steel

while coil springs were continued to maintain space. Lower lateral brackets were then bonded and engaged via a .014

Nickel Titanium segmental wire running from 34 to 44 through the SPEED auxiliary slot. Further activations of lower

laterals were achieved using .016 Nickel Titanium and .018 Stainless Steel, while open coil springs were continued to

open space for the lower canines. Following surgical exposure of the lower right canine, both canines were bonded and

engaged using first a .014 Nickel Titanium and then a .014 x .025 Nickel Titanium wire. Torque expression was achieved

via .018 x .025 followed by .021 x .025 Nickel Titanium. Final torque expression was achieved with .021 x .025 Stainless

Steel with Class II elastics to obtain Class I occlusion.

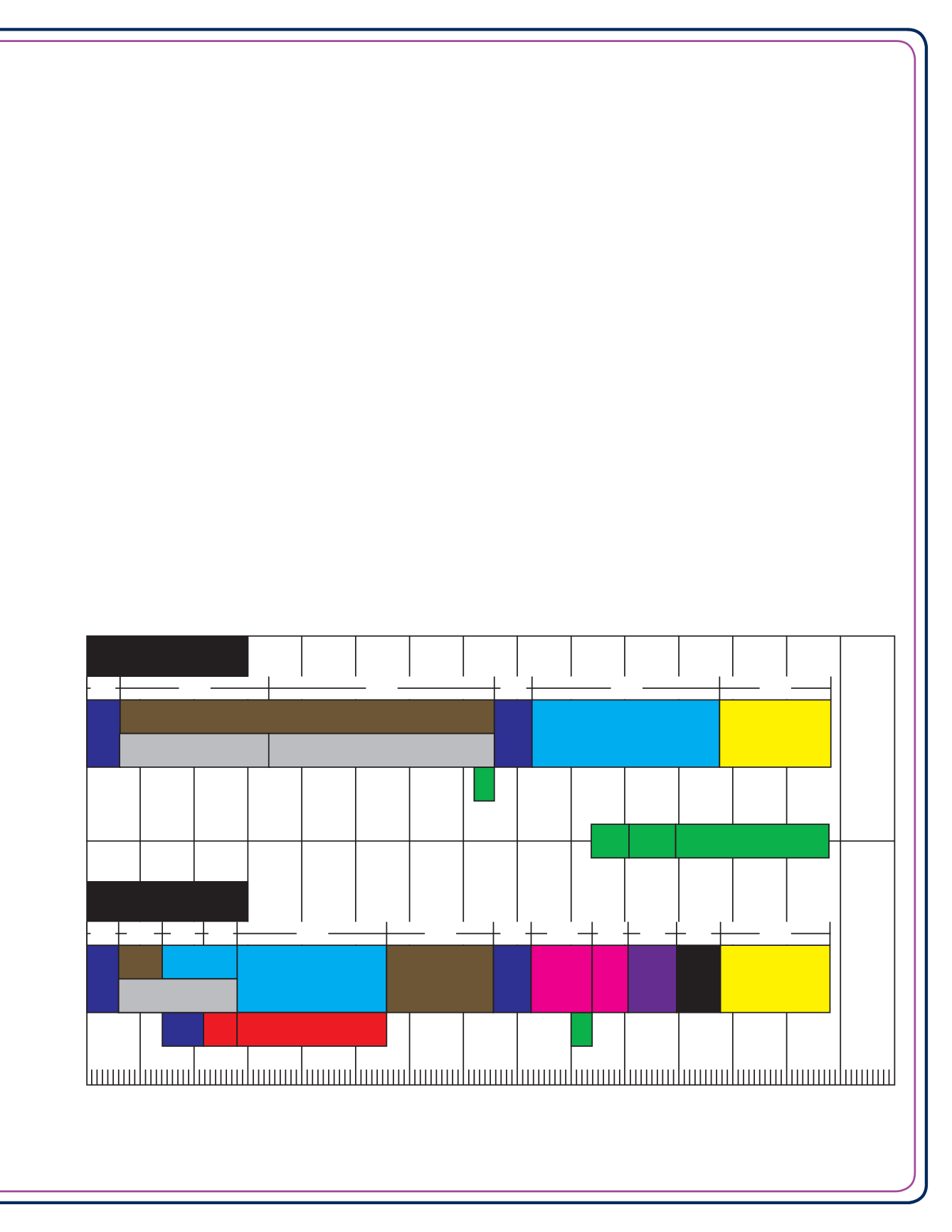

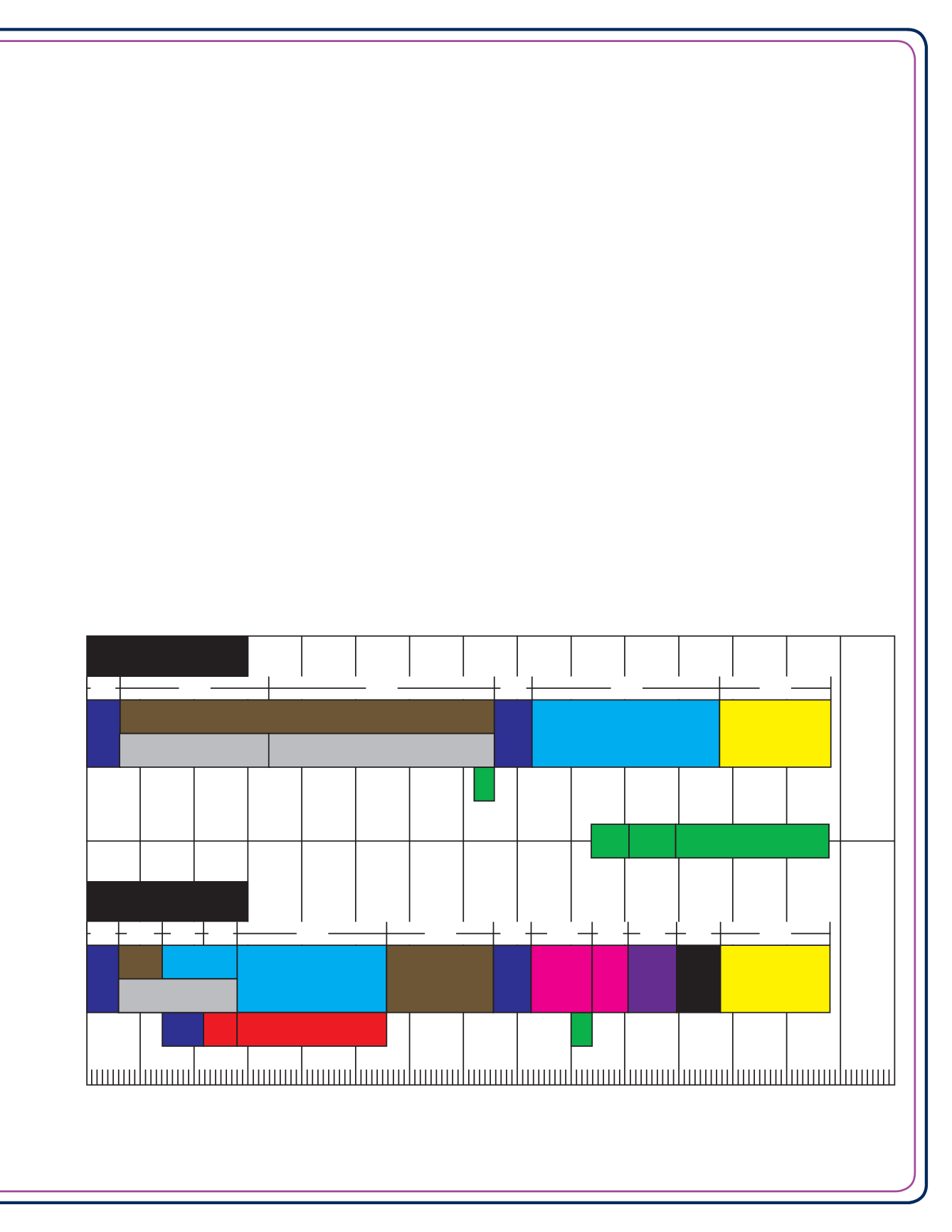

Treatment Utilizing the SPEED Auxiliary Slot - Class I (Non-X)

10

0

20

30

40

50

60

70

80

90

100 110

120 130 140 150

Triangular

elastic

UR3 to

LR3-LR4

CL II

1/4-2oz

elastic

U3 - L6

CL II

1/4-4oz

elastic

U3 - L6

Weeks

L

R

A

#23

L

R

A

#43

6W

6W

8W 8W

29W

19W

11W

20W

7W

7W 9W 8W

6W

28W

33W

20W

7W

Maxillary Arch

Mandibular Arch

44W

.014

SE

.018

SS

.014 SE

segment

.016 SE

segment

.016 SE segment

Open Coil to Open Space

#32 to #34 & #42 to #44

.018 x .025

SS

.018 x .025

SS

.018 SS

Open Coil

#33 To Open Space

Closed Coil

#43 to Hold Space

.014

x

.025

SE

.014 SE

Bond

#33

.014

x

.025

SE

Bond

#43

.018

x

.025

SE

.021

x

.025

SE

.021 x .025

Stainless Steel

.018

Stainless Steel

.014

SE

.018 x .025

Stainless Steel

.014 SE

Bond

#23

Open Coil to Open Space #23

Open Coil to Open Space

#31 to #34 & #41 to #44

Closed Coil #23 to Hold Space

.021 x .025

Stainless Steel

W = Weeks (e.g. 29 W = 29 Weeks)

Archwire Progression: