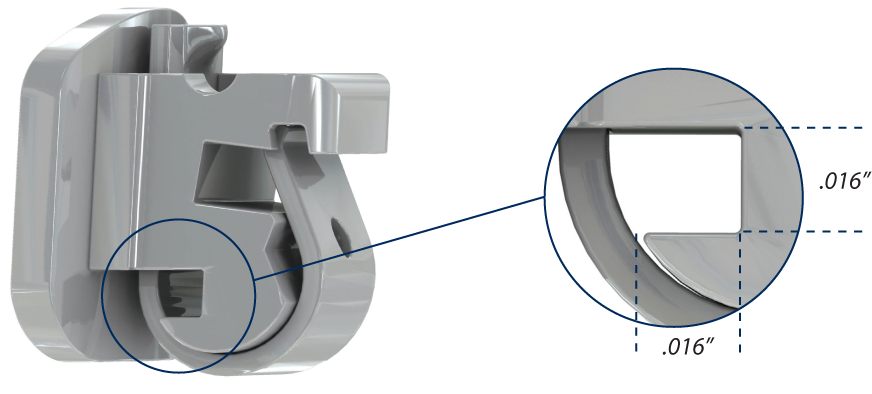

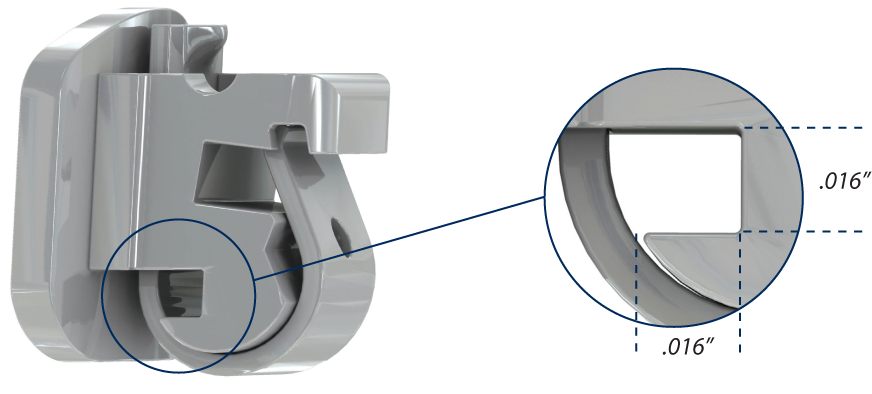

Every SPEED Bracket has two horizontal slots; the archwire slot and the auxiliary slot. The auxiliary slot is located to the occlusal of the archwire slot and is .0165" square in dimension. The auxiliary slot may accommodate:

• Pre-formed SPEED Hooks for elastics

• Secondary archwires

• Sectional archwires

• .016" x .016" auxiliaries

• ligature wires

|

|

SPEED's .016 square horizontal auxiliary slot is often used to house an .016 SPEED Supercable sectional for individual tooth movement. Here a coil is used to create space while the coaxial section gently moves the "blocked out" tooth to its proper location. This is illustrated below in a case that was treated by Dr. Hanson: |

|

July 1993

Despite the severe malalignment, the initial .016 Supercable can slide through the .022 bracket slots with very little frictional resistance. The long pitch of the fine superelastic nickel titanium strands in Supercable and the unique construction of SPEED Brackets combine to create a highly efficient force system for initial alignment. |

|

April 13, 1995

A .016 Tubular Supercable sectional with one end stop is being threaded through the auxiliary tubes of the central and lateral SPEED Brackets.

Before engagement of the canine, the Supercable was pushed gingivally to wrap around the distal of the central incisor.

A stop was placed at the distal of the canine bracket and the excess cut off. Tag ends were eliminated with a small round diamond rotating at slow speed.

The Supercable is dramatically flattened at the distal of the central incisor and where it emerges from the mesial of the lateral SPEED Bracket auxiliary tube. The forces generated by these bends are extremely light and virtually constant over the entire range of activation. |

|

June 7, 1995

The Supercable has sustained no plastic deformation and it has moved the lateral incisor into contact with the coil spring on the .020 stainless steel main archwire. In comparable situations, I now place a step in the archwire to avoid such interference.

This .021x.025 braided nickel titanium archwire will improve the alignment further and begin the necessary torquing movements. A .020x.025 stainless steel SPEED Wire will be used to allow the lateral incisor SPEED Bracket to propel itself fully into its pre-programmed spacial attitude relative to the others. This is accomplished through a unique spring-powered cam action which automatically comes into play when corresponding wire and slot surfaces are not yet in full conformity. |